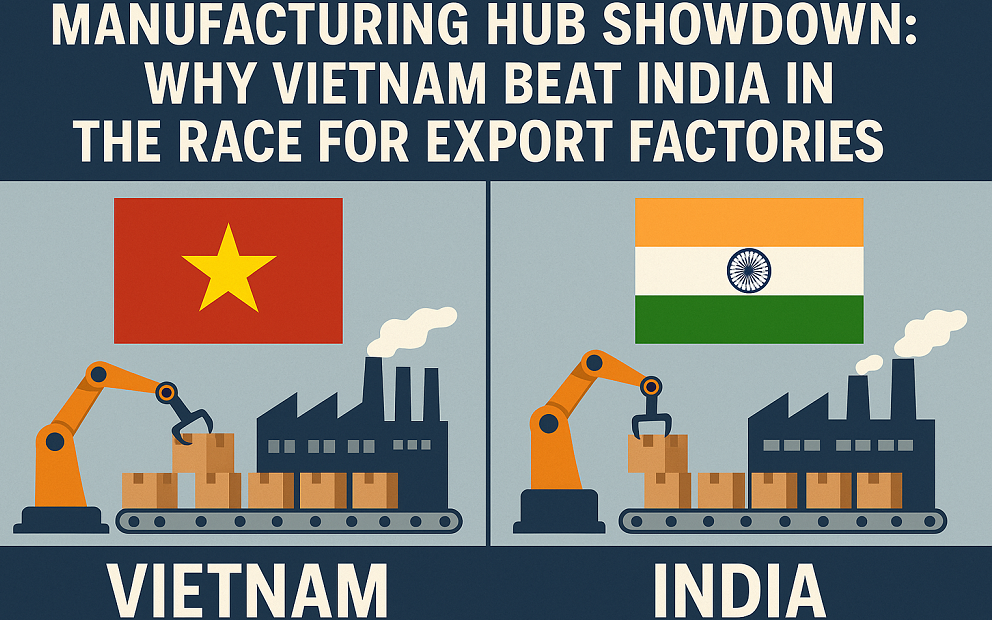

Manufacturing Hub Showdown: Why Vietnam Beat India in the Race for Export Factories

In a world where manufacturing giants are scrambling to diversify beyond China, the unexpected victor of the first wave isn’t India — it’s Vietnam. A nation smaller in size and GDP than many Indian states has, in the span of just two decades, emerged as a global darling for export manufacturing. Whether it’s electronics, apparel, or footwear, Vietnam has outpaced India in attracting factory investments for the global market. Understanding how and why Vietnam won this round is crucial — not just for policymakers and economists, but for anyone who wants to see India reclaim its rightful industrial destiny.

Vietnam’s Early-Game Advantages

Vietnam’s story of success starts with its early bets on openness. Long before the world recognized the fragility of depending solely on China, Vietnam had already signed a string of Free Trade Agreements (FTAs) — from the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) to the EU–Vietnam FTA. These deals opened the doors of Europe, North America, and East Asia to Vietnamese goods, making it dramatically easier for global companies to set up export factories there. Add to this Vietnam’s early WTO membership, a deeply export-oriented economic model, and a strategic geography just south of China, and it was the perfect recipe for becoming a manufacturing hub.

India’s Missed Opportunities

Meanwhile, India’s cautious approach to global trade — highlighted by its withdrawal from the Regional Comprehensive Economic Partnership (RCEP) — kept it isolated from some of the largest free trade zones. India’s historical tilt towards protectionism meant that foreign companies had to navigate complex tariffs, inconsistent state-level regulations, and often glacial bureaucratic processes. While India has always had a massive domestic market, its role as an export-driven manufacturing power remained underdeveloped.

Foreign Direct Investment: The Deciding Factor

Foreign Direct Investment (FDI) was another area where Vietnam raced ahead. By offering one-stop-shop clearances, favorable tax regimes, and ready industrial parks, Vietnam welcomed companies like Samsung, Intel, LG, and Nike with open arms. In contrast, India’s labyrinthine approval systems, costly land acquisition processes, and the specter of bureaucratic red tape deterred many investors during the critical years when global manufacturing was looking to relocate.

Labor Dynamics Tilt the Scale

Labor dynamics further tilted the scale. Vietnam’s compact, young, and relatively well-trained workforce provided high productivity at low cost. Their experience with light manufacturing, especially in textiles and electronics assembly, made it easier for global brands to replicate operations efficiently. India, while boasting the world’s second-largest labor force, struggled with inconsistent skill levels and outdated labor laws until very recently. In sectors like apparel, this gap became painfully evident as brands favored Vietnam or Bangladesh for low-cost, high-speed production over Indian factories.

Can India Still Catch Up?

But all is not lost. In fact, if anything, India is now aggressively repositioning itself. The Production-Linked Incentive (PLI) schemes are beginning to show results, with smartphone exports from India hitting record highs. Infrastructure projects like the Delhi-Mumbai Industrial Corridor and Gati Shakti logistics plan are addressing critical bottlenecks. India’s labor reforms, while slow in implementation, promise a more flexible and industry-friendly environment. Moreover, India’s demographic dividend — a young, expanding workforce — is unmatched by Vietnam, whose population is already beginning to age.

Perhaps most importantly, India is now actively signing new trade agreements with markets like the UAE, Australia, and the EU, building the external linkages that Vietnam had mastered a decade earlier. Global supply chain managers are adopting a “China + Vietnam + India” model rather than choosing just one alternate. In areas like automotive manufacturing, pharmaceuticals, and complex machinery, India already retains a strong edge.

Conclusion: Vietnam Won Round One, But the Match Isn’t Over

In the end, Vietnam won the first crucial round by being faster, more focused, and ruthlessly efficient. India lost time, but not the war. As companies look to hedge their bets and seek both scale and resilience, India’s rise as a manufacturing powerhouse may only be a few reforms away.

As Mr. Arun Durairajan, Partner at Statscope India Research, aptly notes, “Vietnam showed the world how speed and focus can win the first battles of supply chain diversification. But India’s unmatched scale, engineering depth, and hunger for reform mean the final victory in global manufacturing could still belong to India — if we move decisively.”

It’s a lesson written not just in trade statistics or factory floor blueprints, but in the choices India now makes at this pivotal juncture.

This expert article has been written with research assistance from the data science and policy experts at www.statscope.in.